In today’s fast-paced work environments, staying connected is essential. Custom data cables play a critical role in keeping your workspace efficient and organized. Unlike off-the-shelf options, these cables are tailored to your specific needs, ensuring seamless performance. They reduce downtime by delivering reliable connections and help you create a safer, clutter-free workspace. Plus, their cost-effectiveness over time makes them a smart investment for any professional setting. Why settle for standard solutions when you can have cables designed just for you?

Understanding Custom Data Cables

What Are Custom Data Cables?

Custom data cables are specialized cables designed to meet your unique connectivity needs. Unlike generic cables, these are tailored to specific applications, ensuring optimal performance and reliability. Whether you need cables for high-speed data transfer, power delivery, or specialized industrial tasks, custom data cables provide solutions that standard options cannot match.

Some of the most commonly used custom data cables include:

– Shielded Cat6 Ethernet Cables: Perfect for environments with high electromagnetic interference (EMI), such as industrial sites and data centers. These cables minimize signal loss and support fast data transmission.

– Unshielded Twisted Pair (UTP) Cables: Cost-effective and easy to install, UTP cables are ideal for everyday networking tasks like voice, video, and data transmission.

By choosing custom data cables, you ensure that your workspace is equipped with the right tools for seamless connectivity.

How Custom Cables Differ from Standard Options

Custom cables stand out because they are engineered for specific applications. This makes them more reliable and efficient compared to standard cables. Here’s a quick comparison:

| Aspect | Custom Cables | Standard Cables |

|---|---|---|

| Performance | Tailored to specific application demands | General performance, may not meet specific needs |

| Compliance | Engineered to meet strict industry regulations | May not comply with all necessary standards |

| Adaptability | Designed for specific environmental conditions | Limited adaptability to unique requirements |

| Total Cost of Ownership | Lower over time due to reduced maintenance costs | Higher due to frequent replacements and repairs |

| Risk of Failure | Minimized through tailored design | Higher risk due to generic design |

Custom cables are built to last, reducing the need for frequent replacements. They also comply with industry standards, ensuring safety and reliability in your workspace.

Relevance in Professional and Industrial Applications

Custom data cables play a vital role in both professional and industrial settings. For example, a case study from an IEEE paper highlighted the deployment of over 5,000 small cell endpoints using custom cables. These cables provided sufficient power while minimizing installation costs. Centralized power solutions further reduced equipment expenses, showcasing the cost-effectiveness of custom cables.

In industrial environments, custom cables are designed to withstand harsh conditions like extreme temperatures, abrasion, and continuous bending. Testing equipment such as the C-Track Tester and Torsional Tester ensures these cables meet rigorous performance benchmarks. This makes them indispensable for automation, robotics, and other demanding applications.

By investing in custom data cables, you equip your workspace with reliable, high-performance solutions tailored to your specific needs.

Benefits of Custom Data Cables

Enhanced Efficiency and Performance

Custom cables are designed to meet the specific demands of your workspace, ensuring optimal performance. Unlike standard cables, they handle high data loads effortlessly and resist electromagnetic interference. This means you experience fewer disruptions and faster data transfer speeds. For example, in data centers, custom cables minimize energy loss and improve power transfer efficiency. This not only enhances operational performance but also reduces cooling costs, making your systems more efficient overall.

When you choose custom cables, you reduce the risk of downtime. Their tailored design ensures they perform reliably under specific conditions, whether in a busy office or a high-demand industrial environment. By investing in these cables, you create a workspace that operates smoothly and efficiently, allowing you to focus on what truly matters—your work.

Space Optimization and Reduced Clutter

A cluttered workspace can hinder productivity and create safety hazards. Custom cables help you avoid this by offering tailored lengths and configurations that fit your specific setup. Instead of dealing with tangled wires and unnecessary bulk, you can enjoy a clean and organized environment. This not only improves aesthetics but also makes it easier to manage and maintain your equipment.

For instance, custom cables can be designed to combine multiple functions into a single cable, reducing the number of wires you need. This streamlined approach saves space and simplifies cable management. Whether you’re setting up a home office or managing a large industrial facility, custom cables provide a neat and efficient solution that keeps your workspace functional and visually appealing.

Durability and Longevity in Harsh Environments

Durability is a critical factor when choosing cables for demanding environments. Custom cables are built to withstand harsh conditions, including extreme temperatures, abrasion, and continuous bending. This makes them ideal for industrial applications where standard cables would fail. Their robust construction ensures they last longer, reducing the need for frequent replacements and saving you money in the long run.

In addition to their physical strength, custom cables are rigorously tested to meet industry standards. For example, they undergo torsional and abrasion tests to ensure they can handle the stresses of daily use. This level of reliability gives you peace of mind, knowing your cables will perform consistently even in the toughest conditions. By choosing custom cables, you invest in a solution that combines durability with long-term value.

Cost-Effectiveness and Long-Term Savings

Investing in custom cables may seem like a higher upfront cost, but it saves you money in the long run. These cables are designed to meet your exact needs, reducing the risk of failure and the need for frequent replacements. Standard cables often wear out faster because they aren’t built for specific environments or applications. With custom cables, you avoid these issues and enjoy a longer lifespan.

Custom data cables also help you cut down on maintenance expenses. Their durability and reliability mean fewer repairs and less downtime. For example, in industrial settings, cables that can withstand extreme conditions prevent costly interruptions. This ensures your operations run smoothly without unexpected expenses.

Another way custom cables save you money is through energy efficiency. High-quality materials and precise engineering reduce energy loss during data transmission. This lowers your power consumption and cuts down on utility bills. Over time, these savings add up, making custom cables a cost-effective choice for any workspace.

Compliance with Safety and Industry Standards

Safety and compliance are critical when choosing cables for your workspace. Custom cables are designed to meet strict industry standards, ensuring they perform safely and reliably. These standards cover everything from fire resistance to electromagnetic interference, protecting both your equipment and your team.

For example, custom data cables often comply with certifications like TIA/EIA 568-B.2-1 and ISO/IEC 11801. These standards ensure the cables meet specific performance and safety requirements. Here’s a quick overview of some key certifications:

| Standard | Description |

|---|---|

| TIA/EIA 568-B.2-1 | Compliance of cable and connecting hardware to LCL/TCL recommendations. |

| ISO/IEC 11801 | Addresses augmented class E/category 6 (class Ea/category 6A) cabling requirements without distance limitations below 100 m. |

| TIA Standard | Addresses augmented Category 6 (Category 6A) cabling requirements without distance limitations below 100 m. |

By choosing custom cables, you ensure your workspace adheres to these standards. This not only enhances safety but also helps you avoid potential legal or regulatory issues. Additionally, compliance with these certifications guarantees that your cables deliver consistent performance, even in demanding environments.

Custom cables also reduce risks associated with overheating or electrical faults. Their tailored design minimizes these hazards, giving you peace of mind. When you prioritize safety and compliance, you create a workspace that is not only efficient but also secure.

Applications of Custom Cables in Workspaces

Office Environments: Streamlined Connectivity

Custom cables transform office connectivity by providing tailored solutions for your workspace. They eliminate the frustration of tangled wires and mismatched lengths, creating a clean and organized environment. With custom solutions, you can integrate multiple functions into a single cable, reducing clutter and improving efficiency.

For example, custom Ethernet cables can be designed to fit your office layout perfectly, ensuring seamless data transfer between devices. This not only enhances productivity but also improves the overall aesthetic of your workspace. A well-organized office fosters a professional atmosphere, making it easier for you to focus on your tasks without distractions.

Custom cables also support advanced technologies like IoT-enabled devices. These cables ensure reliable connections, allowing you to leverage smart systems for real-time monitoring and automation. By investing in custom solutions, you future-proof your office and stay ahead in a competitive environment.

Industrial Applications: Rugged and Reliable Solutions

In industrial applications, durability and reliability are non-negotiable. Custom cables are engineered to withstand harsh conditions, including extreme temperatures, abrasion, and continuous movement. This makes them ideal for demanding environments like manufacturing plants and construction sites.

The market for cable management accessories is evolving rapidly to meet the needs of modern industries. Organizations now prioritize efficiency, safety, and sustainability. Custom cables, made with innovative materials like flexible polymers and bio-based composites, enhance durability while supporting eco-friendly initiatives. Modular designs and 3D printing techniques further enable quick reconfiguration and reduced waste, catering to the dynamic needs of industrial applications.

Smart cable systems with IoT capabilities also play a crucial role. They allow real-time monitoring, reducing downtime and maintenance costs. By choosing custom solutions, you ensure your industrial operations run smoothly and efficiently, minimizing risks and maximizing productivity.

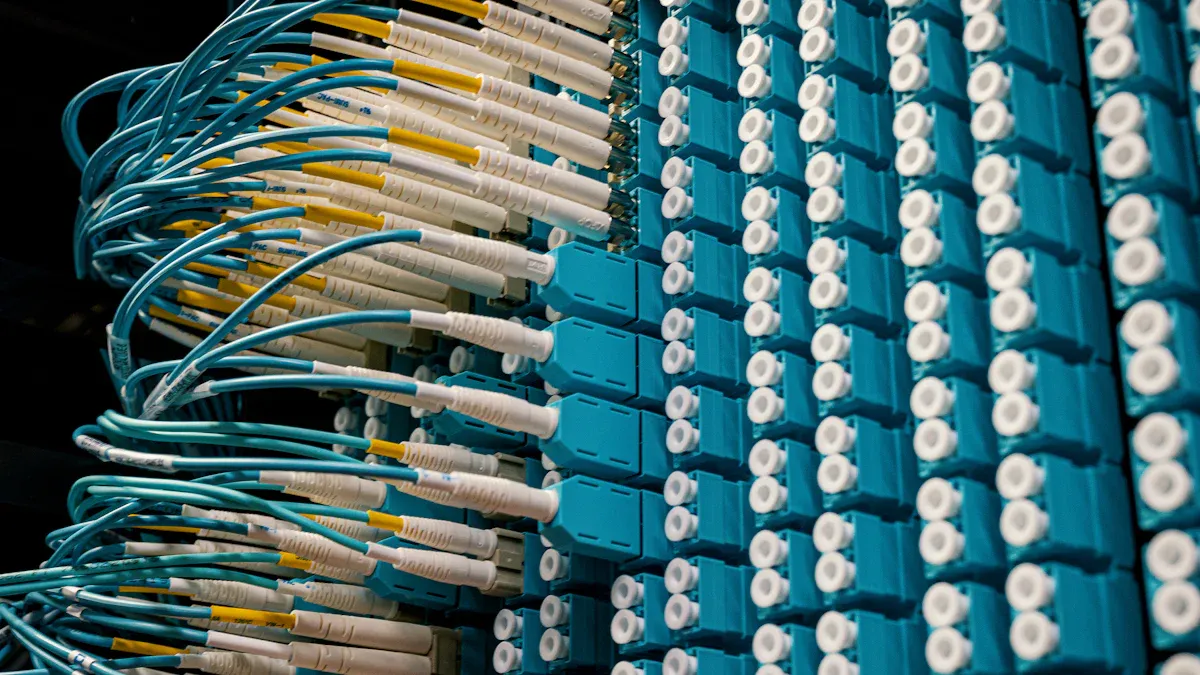

Data Centers: High-Performance Cabling Systems

Data centers demand high-performance cabling systems to handle massive data loads. Custom cables meet these demands by offering superior speed, reliability, and energy efficiency. They are designed to minimize signal loss and electromagnetic interference, ensuring uninterrupted data flow.

Custom solutions also optimize space in data centers. Tailored cable lengths and configurations reduce clutter, making it easier to manage and maintain your infrastructure. Modular designs allow for easy upgrades, ensuring your data center remains scalable as your needs grow.

Energy efficiency is another critical factor. Custom cables reduce energy loss during data transmission, lowering power consumption and cooling costs. This not only saves money but also supports sustainability efforts. By investing in custom cables, you equip your data center with a reliable and future-ready infrastructure.

Choosing the Right Custom Cable Solution

Assessing Environmental and Usage Needs

Choosing the right custom cable solution starts with understanding your workspace’s environmental and operational requirements. Every environment presents unique challenges, and your cables must be equipped to handle them. For example, cables used outdoors need to withstand UV exposure, while those in industrial settings must endure extreme temperatures and mechanical stress.

When assessing your needs, consider the following factors:

– Material Selection: Ensure the manufacturer offers materials suitable for your specific environment, such as flexible polymers for tight spaces or rugged materials for harsh conditions.

– Shielding and Armoring: Opt for cables with shielding to reduce electromagnetic interference or armoring for added protection in high-risk areas.

– Compliance with Standards: Verify that the cables meet industry-specific standards like RoHS and REACH for safety and environmental compatibility.

– Environmental Considerations: Evaluate factors like bend radius, flexibility, and resistance to UV exposure to ensure the cables perform reliably in your workspace.

To further guide your decision, refer to industry standards that assess environmental needs. For example:

| Standard/Requirement | Description |

|---|---|

| IP67 | Protects against dust and water ingress when submerged to a depth of 15 cm up to 1 m for 30 minutes. |

| MIL-STD-810 | Tests materials’ resistance to fungal growth in humid conditions. |

| Environmental Tests | Includes assessments like Thermal Shock, Waterproofness, Vibration, and Salt Spray. |

By addressing these criteria, you ensure your cables are not only functional but also durable and safe for your specific application.

Evaluating Cable Specifications and Compatibility

Once you’ve assessed your environmental needs, the next step is to evaluate the technical specifications of your custom cables. This ensures they align with your operational requirements and integrate seamlessly with your existing systems.

Key specifications to consider include:

– Installation and Operating Temperatures: Cables should function reliably within the temperature ranges of your workspace. For instance, installation temperatures typically range from 0 °C to +60 °C, while operating temperatures can vary from -20 °C to +75 °C.

– Compliance with Safety Standards: Look for certifications like IEC 60754-2 for acid gas testing and Low Smoke Zero Halogen (LSZH) for environmental safety.

– Durability Features: Ensure the cables are resistant to abrasion, chemicals, and other environmental stressors.

Here’s a quick reference table for common cable specifications:

| Specification | Details |

|---|---|

| Installation Temperature | 0 °C to +60 °C (+32 °F to +140 °F) |

| Operating Temperature | -20 °C to +75 °C (-4 °F to +167 °F) |

| Acid Gas Test Method | IEC 60754-2 |

| Environmental Space | Low Smoke Zero Halogen (LSZH) |

| ROHS Compliance | Compliant |

| REACH-SVHC Compliance | Compliant as per SVHC revision |

By carefully evaluating these specifications, you can select cables that deliver optimal performance and reliability in your workspace.

Importance of Supplier Reputation in Custom Cable Manufacturing

The quality of your custom cables depends heavily on the expertise and reliability of the manufacturer. A reputable supplier ensures that your cables meet the highest standards of performance, safety, and durability.

When evaluating a supplier, consider the following:

1. Experience and Expertise: Choose a manufacturer with a proven track record in custom cable manufacturing. Their experience ensures they understand the complexities of your requirements.

2. Certifications and Compliance: Verify that the supplier adheres to industry standards like RoHS, REACH, and ISO certifications. This guarantees the cables meet safety and environmental regulations.

3. Customer Support: Reliable manufacturers offer robust customer and technical support to address any issues or questions you may have.

4. Customization Capabilities: Ensure the supplier can tailor cables to your specific needs, from material selection to length and configuration.

For example, manufacturers that provide Low Smoke Zero Halogen (LSZH) cables or comply with REACH-SVHC standards demonstrate a commitment to quality and environmental responsibility. Additionally, suppliers offering advanced testing methods, such as thermal shock and vibration tests, ensure their products perform reliably under demanding conditions.

By partnering with a trusted supplier, you gain access to high-quality custom cables that enhance your workspace’s efficiency and safety. This investment not only improves performance but also provides long-term value.

Custom data cables offer unmatched benefits that transform your workspace. They boost efficiency by improving power transmission and reducing energy loss. Their durability ensures reliable performance, even in extreme conditions. Plus, they save you money by cutting maintenance costs and optimizing space.

| Benefit | Description |

|---|---|

| Efficiency | Custom cables enhance power transmission efficiency, reducing energy loss. |

| Durability | Designed to withstand extreme conditions, ensuring longevity and reliability. |

| Cost Savings | Lower maintenance costs and optimized space lead to overall savings. |

By choosing custom cables, you create a safe, organized, and high-performing environment. Take the next step and explore solutions tailored to your needs today!

FAQ

What are the main advantages of custom cable assemblies?

Custom cable assemblies provide tailored solutions for your workspace. They improve network reliability, reduce clutter, and ensure compatibility with your equipment. These high-quality cables also last longer, saving you money on replacements. By choosing a custom cable manufacturer, you get products designed specifically for your needs.

How do custom cables enhance network reliability?

Custom cables are engineered to meet your exact requirements. This ensures stable connections and minimizes signal loss. Whether in an office or industrial setting, these cables maintain consistent performance. Their precision design eliminates common issues found in standard cables, boosting your network reliability.

Are custom cables worth the investment?

Yes, custom cables offer long-term value. They reduce maintenance costs, improve efficiency, and last longer than standard options. High-quality cables from a trusted custom cable manufacturer ensure durability and performance. This makes them a cost-effective choice for any workspace.

Can custom cables be used in harsh environments?

Absolutely. Custom cables are built to withstand extreme conditions like high temperatures, abrasion, and moisture. They are ideal for industrial applications where durability is critical. These cables maintain performance even in challenging environments, ensuring reliable operations.

How do I choose the right custom cable manufacturer?

Look for a manufacturer with a strong reputation and proven expertise. Ensure they offer high-quality cables that meet industry standards. Check for certifications and customer reviews. A reliable custom cable manufacturer will provide tailored solutions and excellent support to meet your specific needs.