Imagine a world where your USB cables aren’t just ordinary but tailored to fit your exact needs. Custom made USB cables are transforming how you connect devices by offering flexibility and unique designs. Whether you’re a business looking to stand out or an individual with specific tech requirements, these cables can adapt to your goals. They don’t just work better; they also look great, giving you the chance to showcase your style or brand. Why settle for standard when you can have something made just for you?

What Are Custom Made USB Cables?

Definition and Purpose

Custom made USB cables are designed to meet specific needs, offering a level of flexibility and performance that standard cables can’t match. These cables are tailored for unique applications, ensuring compatibility with various devices and delivering optimal functionality. Whether you’re looking for a cable to transfer high-quality audio data or one that fits a particular device configuration, custom cables provide a solution.

Why are they so effective? It comes down to their construction. Custom cables often use premium materials and components to ensure durability and performance. For example:

– They can be built with shielding to protect against interference, ensuring reliable data transfer.

– The wire size and length can be adjusted to meet your exact requirements, improving safety and usability.

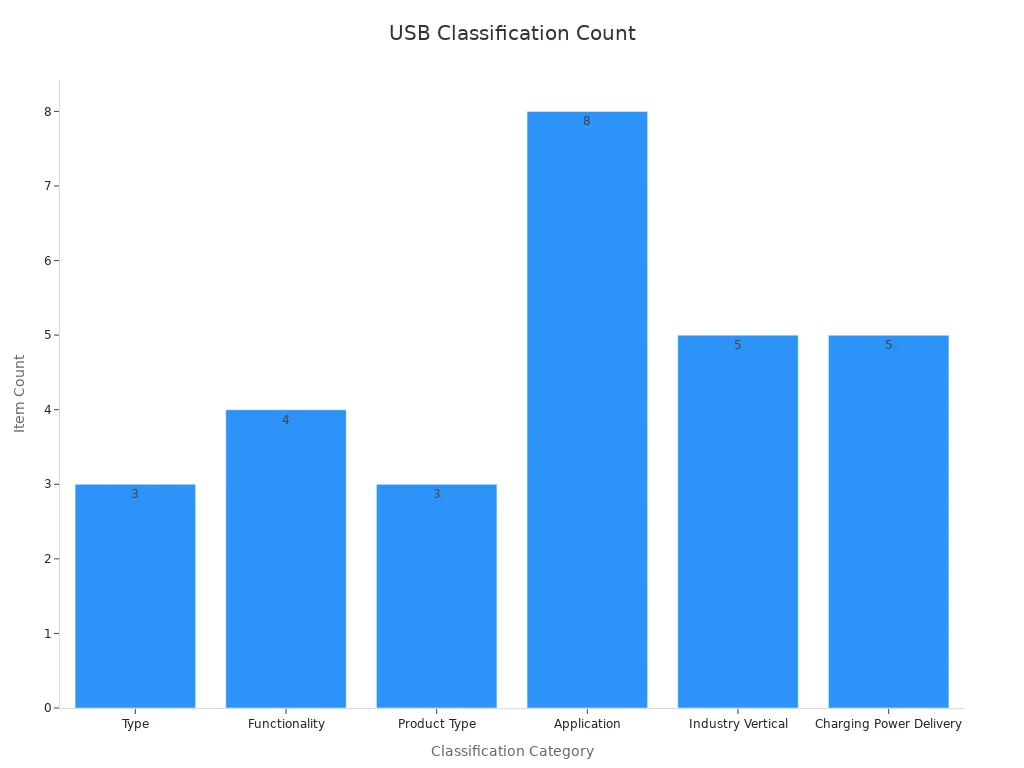

These cables aren’t just practical—they’re also versatile. You can use them for everything from charging your smartphone to connecting industrial equipment. Here’s a quick look at how the industry classifies custom USB cables:

| Classification Category | Details |

|---|---|

| Type | USB Type A, USB Type B, USB Type C |

| Functionality | USB 1.x, USB 2.0, USB 3.x, USB 4 |

| Product Type | USB Data Cable, USB Charger, Multifunctional USB Cable |

| Application | Smartphone, Camera, Camcorder, Printer, Scanner, Computer, TV, Others |

| Industry Vertical | Commercial, IT & Telecommunication, Industrial, Automotive, Healthcare |

| Charging Power Delivery | 0.5 To 15 W, 15 To 27 W, 27 To 45 W, 45 To 100 W, 100 To 240 W |

As you can see, custom made USB cables are more than just wires—they’re tools designed to make your life easier and your devices more efficient.

Key Features and Advantages

Custom made USB cables come with a host of features that set them apart from standard options. One of the biggest advantages is their ability to support high-speed data transfer. For instance, USB 3.0 introduced a “Super Speed” mode, allowing data transfer rates of up to 5 gigabytes per second. Later versions, like USB 3.1 and USB 3.2, pushed these limits even further. This means you can transfer large files quickly and efficiently.

Another key feature is their adaptability. Custom cables can be designed to fit specific devices, ensuring compatibility and ease of use. For example, if you need a USB Type C cable for a modern smartphone or laptop, you can have one made to your exact specifications. This level of customization ensures that your cable works perfectly with your device.

Here are some additional advantages:

– Durability: Custom cables often feature rugged overmolding, making them resistant to wear and tear.

– Compact Design: The connectors are designed to save space, making them ideal for portable devices.

– Cost-Effectiveness: Despite their advanced features, custom cables are often affordable and provide excellent value for money.

In short, custom made USB cables combine performance, reliability, and versatility. Whether you’re a tech enthusiast or a business professional, these cables can enhance your experience and meet your unique needs.

Benefits of Customization

Adaptability for Various Applications

Custom made USB cables are like the Swiss Army knife of connectivity. They adapt to almost any situation, whether you’re working in an office, managing industrial equipment, or setting up a home entertainment system. You can design these cables to fit your specific needs, making them perfect for a wide range of applications.

For example, if you’re in the automotive industry, you might need a cable that can handle rugged environments. Or, if you’re a gamer, you might want a cable that supports high-speed data transfer for seamless gameplay. Custom cables allow you to choose the right length, material, and connector type to match your exact requirements.

Tip: Shorter cables reduce clutter, while longer ones are great for hard-to-reach devices. Think about your setup before deciding on the length.

This adaptability ensures that your devices work smoothly, no matter the scenario. Whether you’re charging a smartphone or connecting a medical device, custom cables make it easier and more efficient.

Branding and Marketing Opportunities

Did you know that your USB cables can double as a marketing tool? Custom made USB cables give you the chance to showcase your brand in a subtle yet effective way. You can add your logo, choose your brand colors, or even print a catchy slogan on the cable.

Imagine handing out branded USB cables at a trade show or including them in a product package. Every time someone uses the cable, they’ll see your brand. It’s a simple yet powerful way to stay top-of-mind with your customers.

Here are some branding elements you can customize:

– Logos: Add your company logo for instant recognition.

– Colors: Match the cable’s color to your brand palette.

– Patterns: Use unique designs to make your cables stand out.

Custom cables aren’t just functional; they’re also a creative way to promote your business. They combine practicality with marketing, making them a win-win for your brand.

Enhanced Functionality and User Experience

Custom made USB cables don’t just look good—they also perform better. By tailoring the cable to your needs, you can enhance its functionality and improve your overall experience.

For instance, high-quality custom cables can transfer data faster, charge devices more efficiently, and last longer than standard options. Here’s a quick look at how they improve user experience:

| Improvement Type | Description |

|---|---|

| Faster Data Transfer | High-quality USB cables transmit data and large files quickly, preventing data loss and ensuring smooth transfers. |

| Improved Charging | High-quality cables charge devices faster, saving time and allowing for more productive activities. |

| Durability | High-quality USB cables can work for a long time without wear, saving money on replacements. |

| Compatibility | High-quality cables are suitable for a range of gadgets, making them versatile for different uses. |

| Safety Features | Investing in high-quality USB cords protects devices from power surges and adverse conditions. |

These improvements make a big difference in your daily life. Faster data transfers mean less waiting. Better charging speeds save you time. And durable cables mean fewer replacements, which saves you money.

When you invest in custom made USB cables, you’re not just buying a product—you’re upgrading your experience. Whether you’re a tech enthusiast or a business owner, these cables offer unmatched functionality and convenience.

Design Options for Custom Made USB Cables

Material Choices and Eco-Friendly Options

When it comes to materials, you have plenty of choices for your custom USB cables. Manufacturers now offer options like nylon braiding, aluminum casings, and even plant-based plastics. These materials not only enhance durability but also cater to the growing demand for eco-friendly products. For example, companies like Nimble use recyclable aluminum and biodegradable plastics to create sustainable cables. They even avoid toxic chemicals and promote e-waste recycling through their packaging.

Why does this matter? Electronic waste is a huge problem. By choosing eco-friendly materials, you’re not just getting a high-quality cable—you’re also helping the planet. Some manufacturers have even developed cables using 70% biodegradable materials, like wood-based substrates. These innovations show that sustainability and performance can go hand in hand.

Customizable Lengths and Shapes

Have you ever struggled with a cable that’s too short or too long? Custom USB cables solve this problem by letting you pick the perfect length. Whether you need a compact cable for travel or an extra-long one for hard-to-reach devices, you can design it to fit your setup. Shorter cables reduce clutter, while longer ones give you flexibility.

Shapes are customizable too. Flat cables, for instance, are great for tight spaces because they don’t tangle easily. Coiled cables stretch when needed but stay compact otherwise. These options make it easier to organize your workspace or home entertainment system. You get a cable that works for you, not the other way around.

Connector Types and Configurations

The type of connector you choose can make or break your cable’s functionality. USB Type C is a popular choice because it’s reversible, fast, and supports multiple functions like data transfer and charging. But that’s not your only option. You can also choose from USB Type A, Type B, or even micro-USB, depending on your device.

Industry standards ensure these connectors perform reliably. For example:

– De Facto Standards: Micro-USB became the go-to for Android phones.

– Industry Standards: USB Type C is now widely adopted for its speed and versatility.

These standards guarantee compatibility and efficiency, so you can trust your cable to work seamlessly with your devices. Whether you’re connecting a smartphone, printer, or industrial equipment, the right connector makes all the difference.

Branding Elements: Logos, Colors, and Patterns

When it comes to custom USB cables, branding is where you can really make them your own. Think of your cables as a blank canvas. You can add logos, pick colors that match your brand, or even create unique patterns. These small details can make a big impact, especially if you’re using the cables for business purposes.

Logos That Speak for You

Adding your logo to a USB cable is like putting your signature on it. It’s a simple way to remind people of your brand every time they use the cable. Whether it’s laser-etched, printed, or embossed, a logo adds a professional touch. Imagine handing out these cables at events or including them in product packages. Your logo will keep your brand fresh in people’s minds.

Colors That Pop

Colors are powerful. They can grab attention and evoke emotions. With custom USB cables, you can choose colors that align with your brand’s identity. For example, if your brand uses bold reds or calming blues, your cables can reflect that. You can even mix and match colors for the cable, connectors, and overmolding to create something truly unique.

Patterns That Stand Out

Want to take it a step further? Add patterns! Stripes, geometric designs, or even custom artwork can make your cables one-of-a-kind. Patterns not only make the cables visually appealing but also help them stand out in a sea of plain black or white cables.

Pro Tip: Use a combination of logos, colors, and patterns to create a cohesive and memorable design. This makes your cables not just functional but also a reflection of your brand’s personality.

Custom branding turns ordinary cables into extraordinary tools for marketing and self-expression. Why settle for plain when you can have something that truly represents you?

Manufacturing and Quality Considerations

Steps in the Manufacturing Process

Ever wondered how custom USB cables come to life? The process is a fascinating mix of precision and technology. Each step ensures the cables meet your expectations for quality and performance. Here’s a breakdown of the manufacturing process:

- Connector Production: Machines create connectors and package essential chips like MFI or E-Marker.

- Cable Production: Metal wires are drawn, annealed, twisted, and coated to form the cable.

- Cable Assembly: Wires are wound according to USB standards, then shielded and insulated.

- Cutting Cable Length: Cables are cut to the exact lengths you need.

- Thermal Stripping: Outer insulation is removed to prepare wires for soldering.

- Soldering the Connector: Connectors are attached using specialized welding machines.

- First Port Shape Injection Molding: A protective mold is applied to secure soldered connections.

- First Electrical Test: Cables undergo their first performance check.

- Second External Injection Molding: A final protective layer is added.

- Second Electrical Performance Test: Another test ensures the cables work perfectly.

- Visual Inspection and Quality Testing: Experts inspect the cables for defects before packaging.

This process ensures that usb cable assemblies are built to last and perform reliably.

Importance of Quality Control

Quality control isn’t just a step—it’s the backbone of manufacturing. Without it, you risk ending up with cables that fail when you need them most. Manufacturers use two main methods to ensure quality:

| Quality Control Method | Description | Pros | Cons |

|---|---|---|---|

| Individual Quality Control (IQC) | Tests each product off the production line for quality assurance. | Accurate depiction of product quality. | Resource-intensive and costly. |

| Statistical Process Control (SPC) | Monitors production processes through statistical methods. | Less expensive and easier to implement. | May allow faulty products to reach consumers. |

To meet industry standards, manufacturers also conduct design validation and compliance testing. These tests check pin configurations, power supply, and cable speed. Neglecting these steps can harm consumer safety and damage a brand’s reputation.

Note: Investing in rigorous quality control ensures your usb cable assemblies deliver consistent performance and reliability.

Ensuring Durability and Reliability

Durability and reliability are non-negotiable when it comes to USB cables. You want cables that can withstand daily wear and tear without compromising performance. Manufacturers achieve this by using high-quality materials and advanced techniques during production.

For example, shielding and insulation protect cables from interference and physical damage. Injection molding adds layers of protection to connectors, making them resistant to bending and breaking. Regular electrical tests ensure the cables perform well under various conditions.

Reliable cables don’t just last longer—they also save you money by reducing the need for replacements. Whether you’re using them at home or in an industrial setting, durable usb cable assemblies make your life easier.

Custom made USB cables offer unmatched flexibility, branding opportunities, and enhanced functionality. They’re not just tools; they’re solutions tailored to your specific needs. Whether you’re a business looking to stand out or an individual seeking better performance, these cables deliver value in every way.

Why settle for standard options when you can have something designed just for you? Explore custom made USB cables today and experience the difference they can make in your daily life.

Pro Tip: Think about your unique requirements before choosing a design. The right cable can simplify your setup and elevate your experience.

FAQ

What makes custom USB cables better than standard ones?

Custom USB cables are tailored to your needs. They offer better compatibility, durability, and performance. You can choose the length, material, and connectors that work best for you. Plus, they can include branding elements like logos and colors, making them unique and functional.

Can I use custom USB cables for all devices?

Yes! Custom USB cables can be designed for almost any device. Whether it’s a smartphone, printer, or industrial equipment, you can create a cable that fits perfectly. Just make sure to specify the connector type and functionality you need.

Are custom USB cables eco-friendly?

They can be! Many manufacturers now offer eco-friendly materials like recyclable aluminum or biodegradable plastics. Choosing these options helps reduce electronic waste and supports sustainability. 🌱 It’s a great way to get high-quality cables while caring for the planet.

How long does it take to make custom USB cables?

The production time depends on the complexity of your design. Simple cables might take a few days, while more intricate designs could take a couple of weeks. Always check with the manufacturer for an accurate timeline.

Are custom USB cables expensive?

Not necessarily. While they might cost more than standard cables, they offer better value. You get a product designed specifically for your needs, which often lasts longer and performs better. Think of it as an investment in quality and convenience.

Tip: Compare prices from different manufacturers to find the best deal without compromising quality.